Applications

At Pitcrew AI, we understand the need for safety and best asset utilisation in 24/7 mining operations.

Our advanced AI-based solutions are designed to keep your workforce safe and your operations running smoothly, minimising unscheduled downtime and maximising productivity.

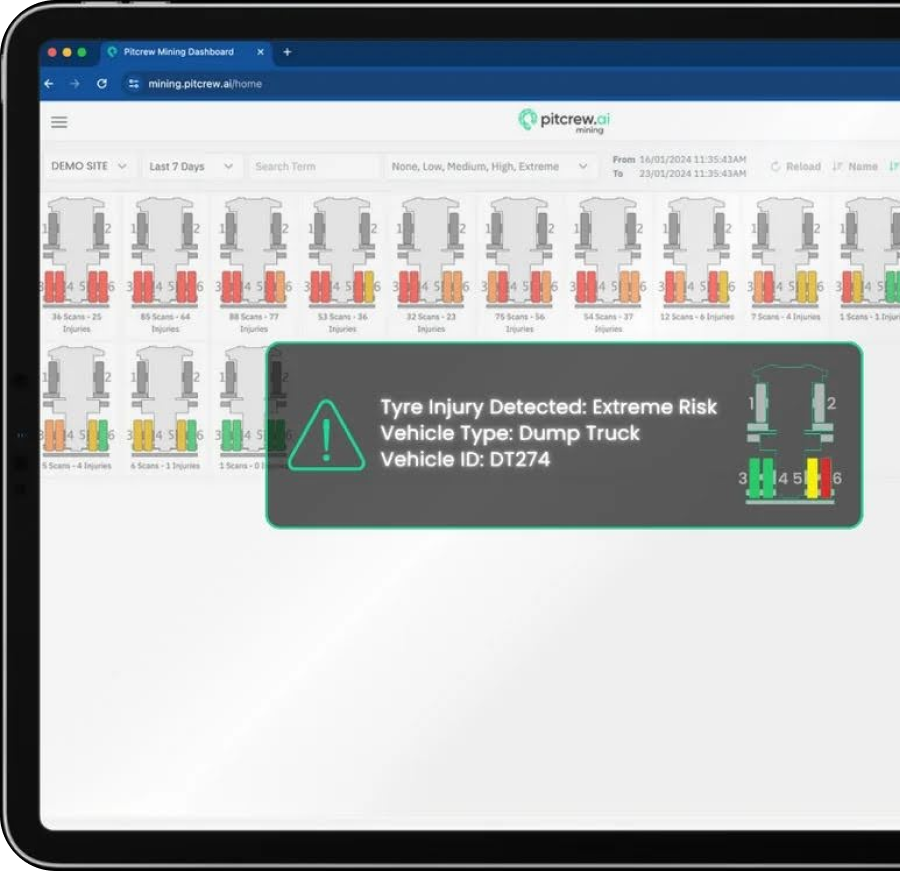

Real-Time Condition Monitoring

Our cutting-edge technology continuously monitors the condition

of your mining transport equipment in real-time. By detecting potential issues before they become critical, we help you avoid costly breakdowns and ensure the safety of your operations.

AI-Based Assessments

Leveraging advanced artificial intelligence, our system provides precise and reliable assessments of your equipment’s health. This enables proactive maintenance and reduces the risk of unexpected failures, keeping your mining operations efficient and secure.

Enhanced Safety

Safety is at the core of everything we do. Our autonomous monitoring technology significantly reduces the risk of accidents by providing early warnings and detailed insights into equipment performance. This ensures a safer working environment for your team.

Increased Productivity

By minimising downtime and optimising equipment performance, our solutions help you achieve higher productivity levels. Real-time data and predictive analytics allow you to make informed decisions, improving overall operational efficiency.

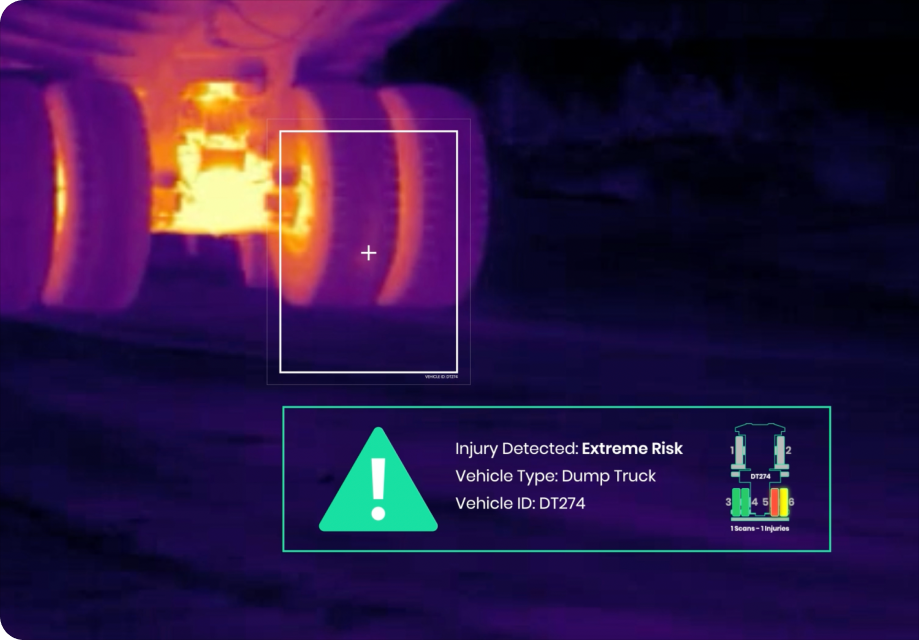

Advanced Computer Vision

Our technology uses advanced computer vision to accurately identify and diagnose potential issues in your mining equipment. This allows for precise monitoring and timely interventions, ensuring your operations run smoothly.

Predictive Analytics

We combine real-time data with predictive analytics to forecast potential equipment failures. This proactive approach helps you schedule maintenance activities effectively, reducing downtime and extending the lifespan of components.

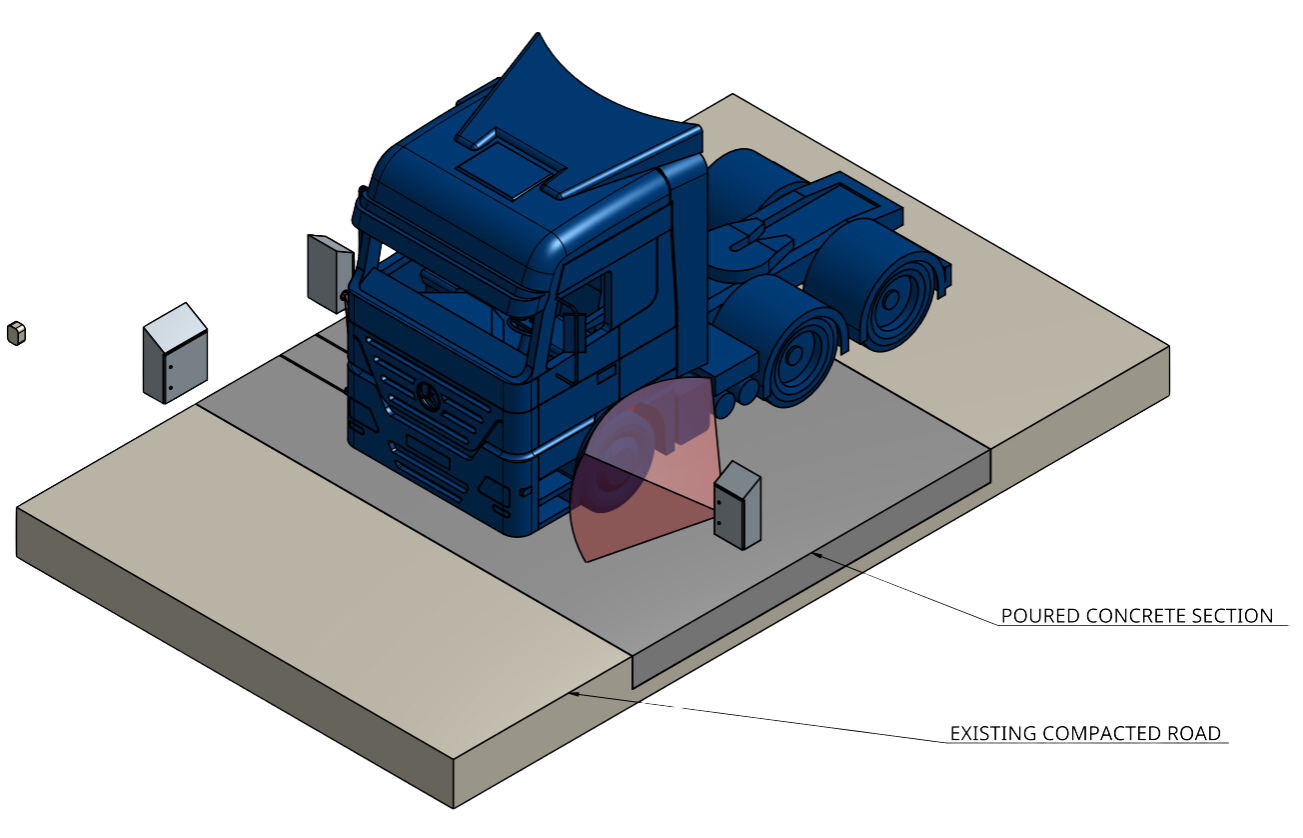

Autonomous Monitoring

Pitcrew AI’s autonomous monitoring system operates without human intervention, providing continuous oversight and rapid alerts. This ensures that potential issues are addressed promptly, keeping your equipment in optimal condition.

Our cutting-edge technology is designed specifically for transport authorities, streamlining compliance checks for heavy vehicles.

On Road

Value drivers:

- Inspect:

- Brakes

- Wheel hubs and bearings

- Tyre surface temperature (underinflation)

- Detect maintenance issues as vehicles enter the depot

- Enables planned maintenance, reducing roadside breakdowns

- Chain of responsibility and safety for all road users.

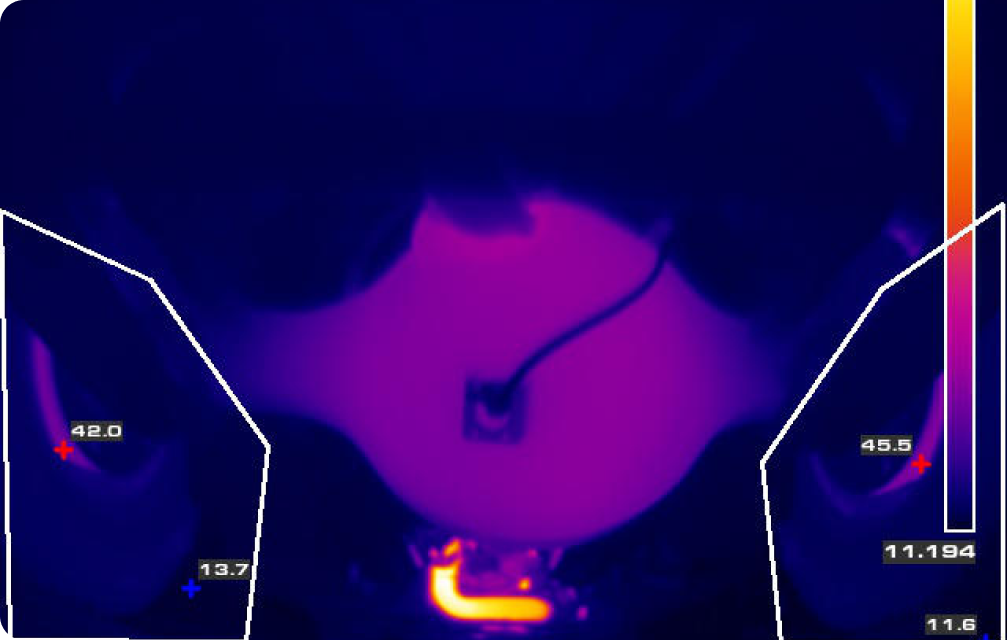

These cameras detect temperature differences by capturing thermal radiation intensity. They’re incredibly precise, measuring over 300,000 separate points simultaneously.

Pitcrew Compliance identifies malfunctioning brakes, overheated bearings, and other tire risks through thermal anomalies. Defective brakes, for instance, appear colder than operational ones—a clear distinction visible on thermal images.

Web-Based User Interface (Web UI)

Near real-time insights

Near real-time insights

As vehicles move over the camera, near real-time results are gathered. The video stream provides rapid insights.

Axle Assessment

The system automatically detects the number of axles and individually analyses each one. An assessment frame shows the temperature differential between the brakes.

Pass or Fail

Based on the assessment, each axle receives a ‘Pass’ or ‘Fail’ rating. Operators can take prompt action to address any issues.

Pitcrew AI systems offer real-time, automated condition monitoring for your fleets, providing significant advantages over periodic manual inspections.

Safety and Responsibility

Ensure drivers operate safe vehicles, fulfilling your duty of care.

Enhance road safety for all public road users upholding the chain of responsibility.

Maintenance and Efficiency

Proactively detect issues before they escalate, reducing repair costs and avoiding roadside breakdowns.

Compliance and Regulation

Simplify statutory compliance. Automate inspection records, avoid defect notices, and keep your fleet compliant and on the road.

Environment and Community

Extend component life, reduce your carbon footprint, and maintain public safety to uphold your social licence to operate.